Project:

Role:

Client:

Make To Stock Planning Process

Consultant

Release liner company

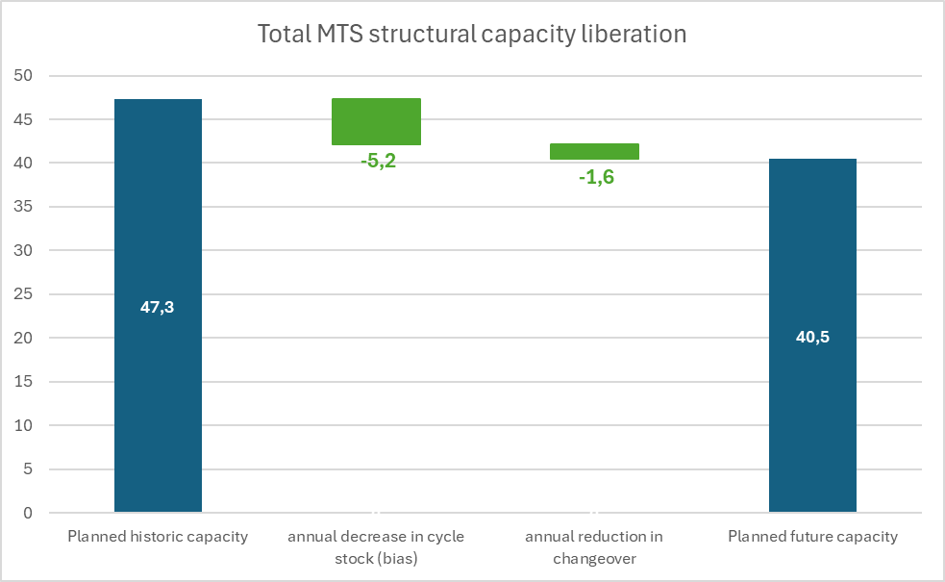

Design and implementation of a process for Make to Stock clients (as opposed to Make to Order clients) to liberate scarce production capacity and create commercial flexibility

Economic Production Quantity calculation to show potential trade-off between changeover costs and inventory costs

Safety stock parameters determined based on realistic process reliability:

Forecast accuracy

Production reliability

Customer and SKU segmentation

Decision making process (S&OE) introduced to enable agility and responsiveness towards all customers

Design of planning policies and Make to Order process to ensure an end-to-end solution

Liaison with the global supply chain team to enable a successful SAP-IBP implementation and the journey to Oliver Wight Class A